July 2016

Improving techniques for Crossrail Driver Only Operation CCTV design

Fri 1st July, 2016

Engineers at Fourway have developed a technique to improve the process for designing platform CCTV systems.

DOO or OPO CCTV has been extensively used on our rail networks for over 40 years to provide drivers with the assurance that the train doors are closed and it is safe to depart. The platform-train interface remains a safety issue with boarding and alighting representing around 11% of all passenger accidents. Developing the right system is of critical importance to the operation of the railway and safety of the travelling public.

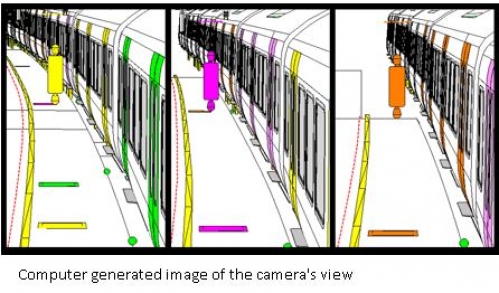

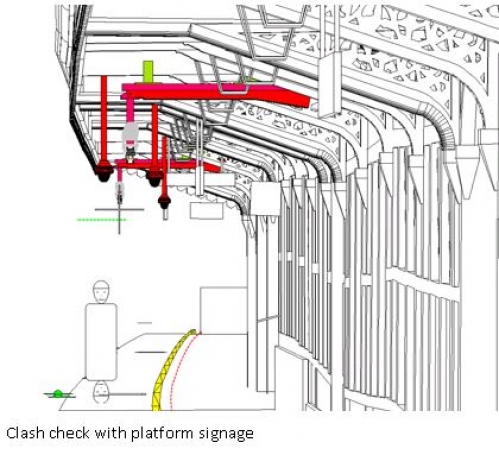

Like any operationally-critical system the design process must lead with safety while also considering system performance, sustainability, cost, constructability etc. At its heart, driver's CCTV is an assessment of optical requirements together with the camera & lens selection and positional envelopes. The design has to consider the presentation of the train doors, which in turn, are affected by track cant and curvature, stepping and gauging clearances, multiple train stock types and stopping positions. There are a host of other considerations such as clashes with station assets, heritage, vandalism, sunlight, signal sighting, proximity to OLE, availability of cable routes and mounting method. Throughout, the process must design out safety risk from both a construction and maintenance perspective. We deploy best practise to reduce this risk. For example, bracket families which can be pre-assembled in a factory environment to reduce installation time or equipment that swings away from the tracks so it can be maintained in a safer environment, with a reduced need for safety staff or working at height.

In addition each stage of design has to consider value. Typically we achieve savings by designing the most efficient distribution of cameras, reusing existing mounting arrangements and cable routes etc. But also we take a whole-life view considering how the system will attract cost throughout its lifecycle. For example ensuring fixings are easy to inspect or that parts can be easily accessed and exchanged etc.

We rarely have the luxury of a green field site. In most cases we are developing design for an existing built environment. In the case of our Crossrail DOO systems we have a hybrid condition with existing stations which are themselves going through a process of change in preparation for Crossrail such as track & platform re-alignment, OLE upgrade, platform extensions and new overbridges all of which impact system design. Our interfacing data, is therefore part- provided by surveying and part by other designers. Verification of conflicting data is critical to our design and embedded in our methods of 3D modelling.

Our proprietary modelling tool, has been developed for DOO CCTV design over the past 15 years and includes:

• Multiple cross-checking formulae which inform the design and are then verified by an independent engineer.

• Predictions put into 3D CAD model and resulting camera views checked against the Crossrail DOO Standard for compliance. This method is sensitive enough to pick up small variations in the CAD model where point cloud data has been converted into solid shapes.

• Predictions used for camera view surveys and captured views compared with 3D CAD model. This also does a number of fundamental checks such as does the CAD model match reality? It also includes a ‘round-trip’ of the conversion from linear platform measurements to actual GPS coordinates and back again, to remove an obvious source of potential error.

The modelling tool contains numerous checks and tests for compliance with a wide range of parameters and gives graduated results showing marginal values and reduced tolerances that might affect the ability to compensate for future stepping and gauging changes. It also improves the accuracy of clash checking to help other disciplines validate their designs and thus increases overall efficiency.

Fourway are currently utilising these techniques for the Crossrail DOO CCTV system design at 14 stations between Maidenhead and Paddington, a total of 44 platforms. Completion of GRIP 5 design is currently scheduled for 2017.