September 2015

GRIP 5 design nears completion at East West Rail Phase 1

Thu 10th September, 2015

The Bicester to Oxford Collaboration programme is being delivered by an integrated project team comprising Network Rail, Chiltern Railways and a joint venture led by local companies Carillion and Buckingham Group Contracting with support from the East West Rail Consortium, a group of local authorities including Oxfordshire County Council.

The upgrade not only allows Chiltern Railways to operate a new service between Oxford and London, but will be the first phase of work on the western section of the East-West Rail project, which will reinstate a railway for passengers and freight to Milton Keynes and Bedford. By combining the two projects they can be delivered more efficiently and with less disruption for rail users. Features of the project include: a new 1km section of railway to join the Chiltern mainline; widening the existing track bed; doubling over 18km of track; increasing the speed that trains can travel to 100mph; constructing new road bridges, under bridges and footbridges; closing 37 level crossings to improve safety; three new stations; installing a new signalling system.

As part of our design and construct contract, Fourway provided the GRIP 5 mechanical, electrical, public health, SISS and DOO CCTV disciplines. The principal area of activity was to support the construction of three new stations located at Oxford Parkway, Bicester Village and Islip.

Working for the Carillion-Buckingham JV we formed part of their core design team alongside engineering consultant SKM Jacobs. Our design was structured around separate NR form 3 design submissions for each station and each discipline. Design collaboration was assisted through use of the Aconex project management system and a high degree of co-location at site offices.

Our CAD team shared a common project model for all architectural and spatial data. This ensured consistency of the design environment across all disciplines.

At GRIP 5 our focus was buildability, co-ordination and looking at ways we could reduce construction cost. An example to illustrate this was adopting the Institute of Lighting Professionals lighting design guidelines to reduce the number of car park lighting columns and prevent light spill to local residents. The required lux levels were still achieved but with a 20% saving in associated civil works for bases and duct runs.

Scope details:

Electrical

We prepared detailed layout designs for the switch room including specifying DNO incoming supply, main switchboard, sub-main feeder cables and final distribution systems.

We utilised Amtech software to determine cable sizing and distribution requirements. We designed the supplies for 4 lifts and all platform and station ticket/passenger information (SISS) systems.

The earthing & bonding design was in compliance with BS7671. We provided passive provision for future electrification. Lightning protection design covered footbridges, station buildings and steelwork.

Small power

We provided a design which was co-ordinated with the project architects, SISS and the cable containment design. The object was to reduce the amount of visible cable as far as practical.

Containment

We produced a fully co-ordinated cable containment design. One important facet was co-ordination with civil designer to ensure there was complete continuity of cable route capacity through transitions from containment to below ground duct.

Building Management Systems

The station buildings included BMS incorporating separate accessible energy sub-meters with a pulsed output to enable connection with space heating, domestic hot water, humidification, cooling, fans and lighting.

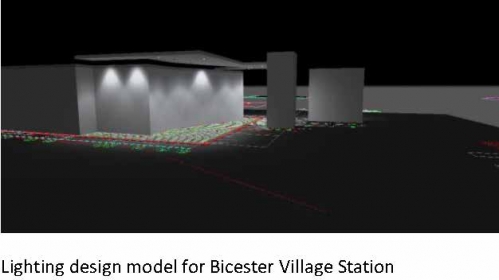

Lighting

Lighting design was predominantly undertaken using Dialux to achieve relevant uniformity and lux levels in compliance with NR Standards. We specified low-energy LED lighting in all internal and external areas. External lighting was concentrated in the appropriate areas with upward lighting minimised to reduce unnecessary light pollution, energy consumption and nuisance to neighbouring properties.

We developed our own lighting controls system design for each station to provide car park reduced illumination levels in ‘out-of-hours’ and provide lighting controls to internal areas in compliance with BRE Digest 498.

Heating, Ventilation and cooling

Building design optimised the use of natural ventilation where possible. Powered ventilation was provided for back of house areas. A heat exchanger was incorporated to utilise waste heat.

The design incorporated air source heat pumps to provide a low carbon means of heating and cooling back of house areas.

We specified point-of-use water heaters to avoid pipe work losses and reduce risk of legionella. All cold and waste water pipework designs were supported with flow and capacity calculations.

BREEAM

We considered sustainability throughout our design helping the project to gain a ‘very high’ BREEAM rating. Initiatives included selecting low carbon systems including lighting, air source heat pumps, urinal flush presence detectors, tap water flow sensors, ventilation heat exchanger and WC dual flush. We provided input to the project’s BREEAM technical manual.

Station Information & Security Systems (SISS)

We provided the design for all communication systems including interfaces with the wider railway. We designed communications equipment rooms and the station staff’s customer information points. We provided passive provision for Chiltern Railways’ WAN equipment and other IT requirements including ticket vending machines, wifi, gate lines and BT services.

We developed day and night CCTV coverage for all public areas of the station and car parks; the station data network provided an IP platform for full digital video recording.

Our customer information design included Next Train Indicators (NTIs) on the platforms and a Summary of Departures (SoDs) in ticket halls. The design was based on Chiltern Railways’ CIS system, hosted on a server at Marylebone, and managed from workstations at a number of locations including Banbury ICC. We provided two types of help points. Those for passengers requiring general information and ‘refuge help points’ to allow passengers held in fire refuges to communicate with staff.

Public address systems were specified on platforms and in the public areas of the station. We carried out acoustic modelling in the station building and produced desktop calculations for the platforms.

The intruder detection system was designed to EN50131 Grade 3 and provided to protect the station building against intrusion whilst unoccupied.

DOO CCTV

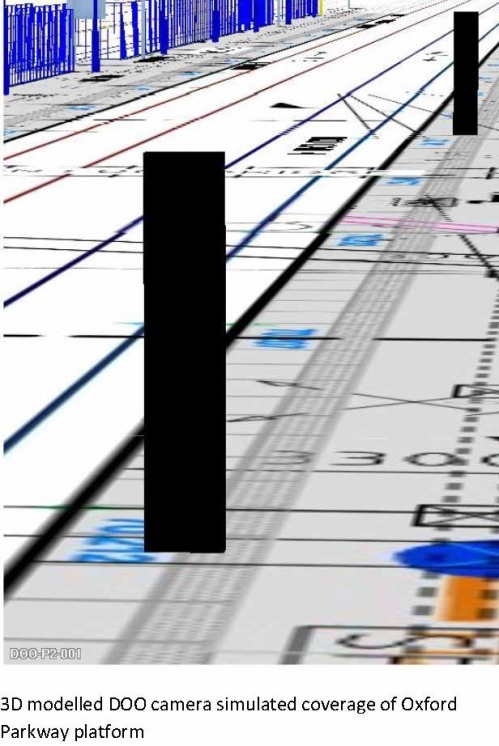

We designed 12 independent look-sideways DOO systems for normal and reverse working.

We used 3D software to model camera coverage and produce simulated views of the platform-train interface. Up to six cameras are positioned along the platform to provide images of trains journeying in both the up and down directions.

Monitors were positioned on the driver’s left side, with the front of train camera view displayed on the top right hand monitor.

We defined the civil requirements for camera posts and cabinets. Those located in the cess were provided with maintenance access in accordance with NR/CIV/SD/670.

DOO impact assessment on signal sighting was undertaken by Gioconda.

Production design (GRIP 5)

Our production design was aimed at providing the detail and clarity needed by site teams helping to ensure that the quality and consistency of the final installation was properly controlled.

The site teams were also consulted during the drawing production process. Issues raised by installers got addressed and embedded in the production drawings thereby improving efficiency. The drawings also pre-defined much of the fabrication and assembly, enabling much to be done off-site in a safer, lower cost environment.

We also saw advantage in overlapping this phase of design with implementation. It allowed critical parts of the work to be constructed such as equipment rooms, platform canopies etc. This allowed us to survey final positions and define much of the setting out from actual dimensional data. This reduced the risk of clashes and the amount of reworking by installers.